Spring Winding Tools: Why They Save Time, Money and Effort

Knowledge centerEfficient spring winding is essential for safety and productivity. Traditional methods can be time-consuming and physically demanding, but modern spring winding tools simplify the process. By reducing strain, increasing speed, and enhancing precision, these tools help you save time, lower costs, and improve overall efficiency.

Built to Last

Durable stainless steel and bronze construction for long-lasting performance.

High Torque Power

Delivers up to 285 Nm of torque for handling heavy springs.

Reduced Manual Effort

Ergonomic design minimizes strain and makes operation easier.

Safe and Secure Winding

Reduced risks compared to using traditional winding bars.

Become a partner

Are you interested in partnering with DOCO and do you want full access to our webshop, configurators and more? Contact us now and plan your visit or online meeting. Plan your meeting nowFeatures

Our Spring Winding Tools

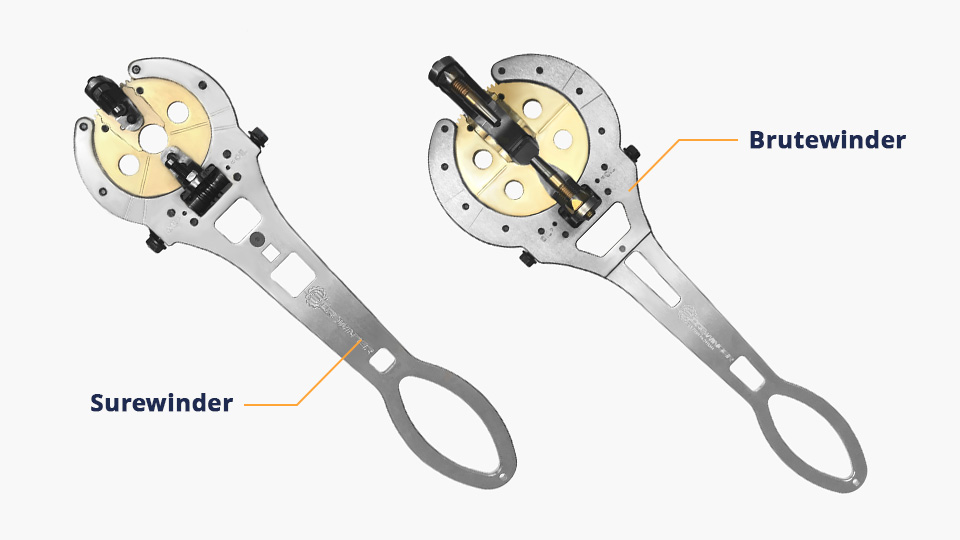

At DOCO, we have two high-quality, robust spring winding tools in our assortment: the Surewinder and the Brutewinder. The Surewinder is the original spring winding tool, specifically designed to safely and efficiently handle residential spring winding tasks. For industrial applications, the Brutewinder is our most powerful spring winding tool, built to tackle the biggest and most demanding industrial spring winding needs.

Designed for Efficiency and Safety

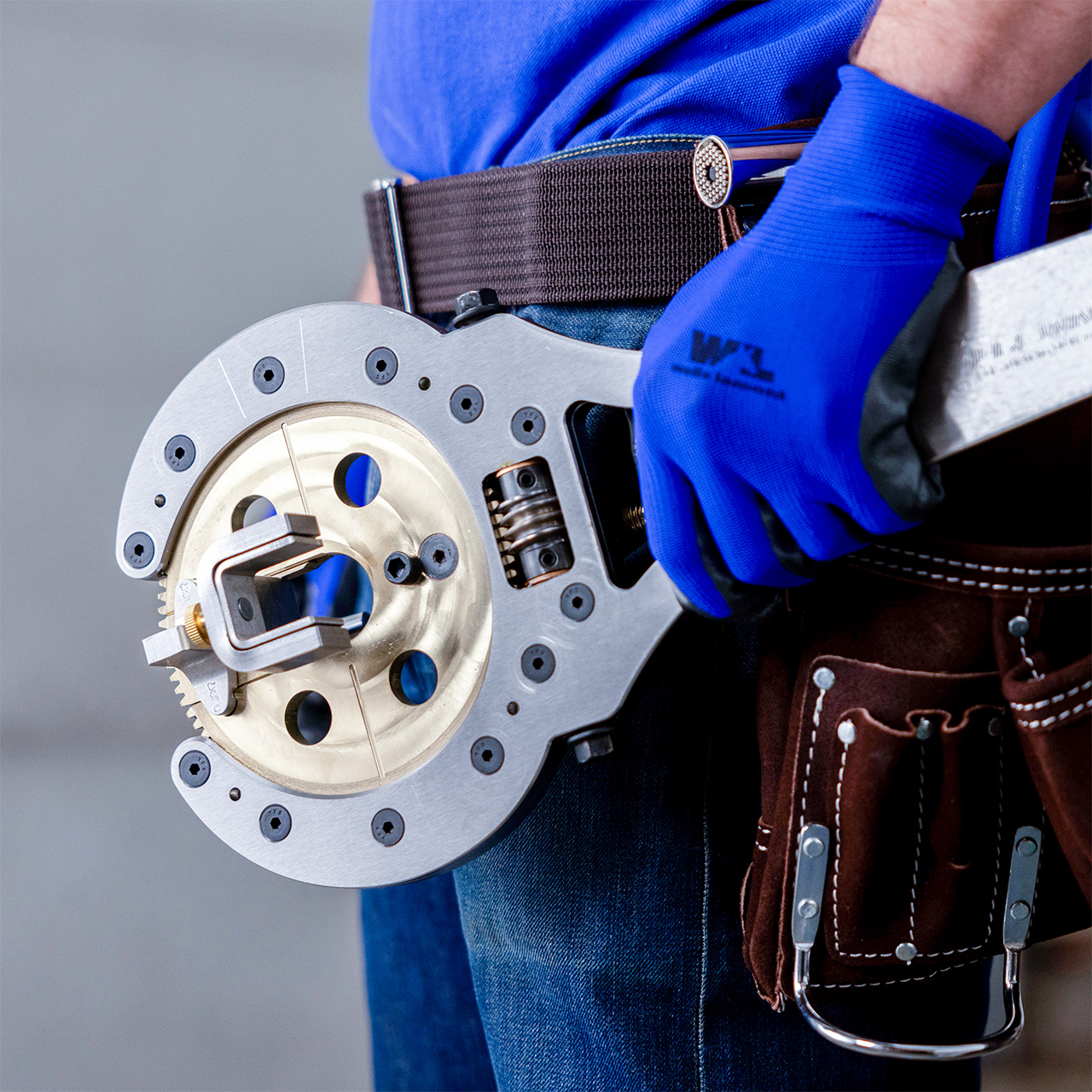

Our spring winding tools are designed to improve safety and efficiency in your work. The torque-stabilizing technology does the heavy lifting, providing a more ergonomic experience compared to traditional winding bars.

Unlike bulky alternatives, our tools are remarkably lightweight without compromising strength, making them easier to handle and reducing strain during use.

Improve efficiency with a safer, more controlled approach to winding and unwinding springs. Reduce fatigue, minimize risks, and complete jobs with greater ease and confidence.

Crafted from durable stainless steel and high-temper bronze, these tools offer strong wear resistance and reliability. Designed with precision engineering and used in the field for over a decade, they are built to withstand demanding tasks.

Brutewinder

How does it work?

Our spring winding tools use a worm gear system powered by a low-RPM, high-torque drill to wind springs in under three minutes with minimal effort. Its design prevents the spring from unwinding on its own, ensuring a safe and controlled operation. This proven safety mechanism is commonly used in winches and other high-safety applications.

Have a look at the instruction video for an in-depth explanation.

Surewinder vs. Brutewinder: comparing our spring winding tools

| Feature | Surewinder | Brutewinder |

|---|---|---|

| Application | Residential & light industrial | Industrial |

| Max. torque rating | 115,8 Nm | 285 Nm |

| Max. wire thickness | 9 mm | 12 mm |

| Nut for driving | 14 mm with a 6-point socket | |

| Min. clearance area (from shaft to wall) | 64 mm | 89 mm |

| Suitable spring diameter | 51 - 95 mm | 51 - 152 mm |

| Suitable shaft diameter | 25,4 mm (1”) | 25,4 mm (1”) & 31,75 mm (1,25”) |

| Weight | 3,4 kgs | 5 kgs |

| Size of tool | 533 x 152 x 89 mm | 625 x 206 x 127 mm |

| Material | 304 stainless steel & bronze | |

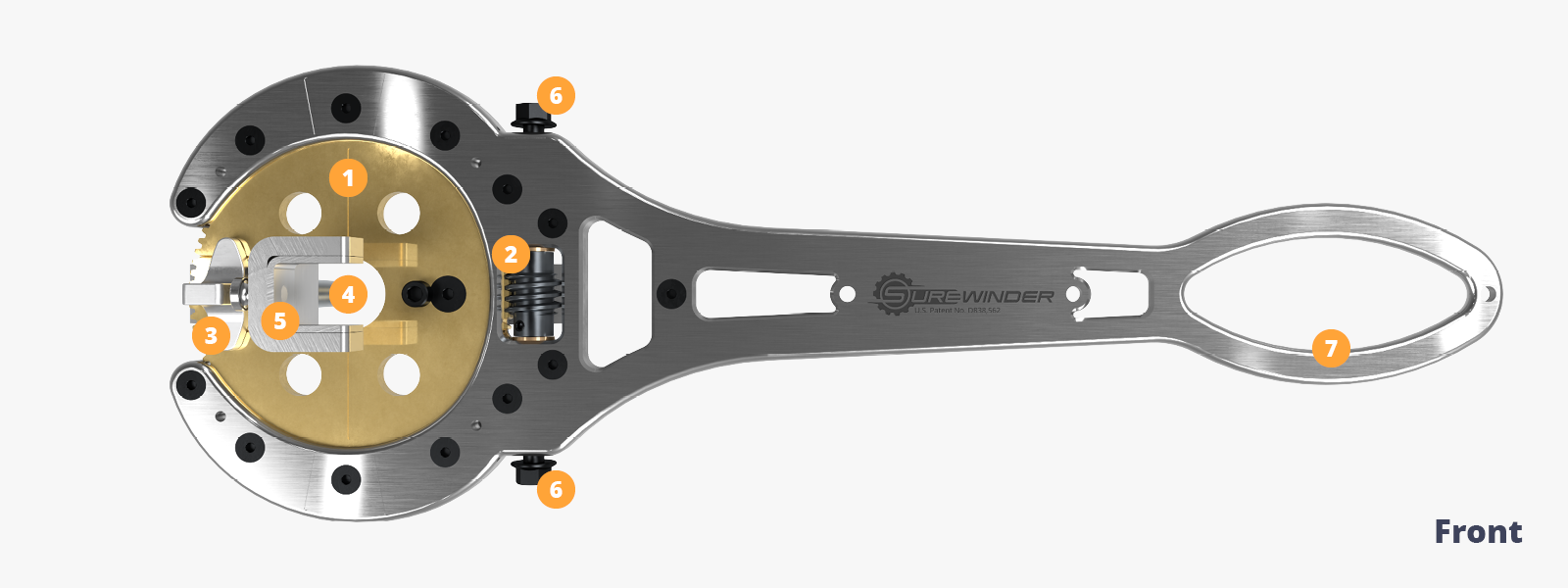

The Brutewinder in Detail

-

Worm Wheel

This high-temper bronze component connects to the worm gear, enabling the rotation of the spring plug with precision and durability.

-

Worm Gear

Responsible for managing the torque force of the winding tool, this essential mechanism requires regular greasing to ensure smooth and optimal performance.

-

Thumb Latch

Acts as the locking mechanism for securing the detachable drive pin during the use of the winding tool. It allows for quick mounting and demounting onto the spring plug in a single motion.

-

Shaft Passage

The area where the shaft passes through the tool. The Surewinder accommodates 25.4 mm (1”) shafts, while the Brutewinder can also handle 31.75 mm (1.25”) shafts.

-

Shaft Stabilizer

Designed to securely stabilize the tool onto the shaft during operation, the stabilizer accommodates 31.75 mm (1.25”) shafts by default. With the removable insert in place, it can securely handle 25.4 mm (1”) shafts.

-

Winding Screw

These 14 mm (3/8”) hexagon screws are designed for attaching your drill to wind or unwind the spring.

-

Ergonomic Handle

A lightweight yet sturdy handle designed for ergonomic use. The integrated opening allows for easy attachment of a rope or carabiner for added convenience.

-

Drive Pin

The tool consists of two drive pins, each attached to a flange. One flange is permanently fixed to the winding tool, while the other must be clamped on during operation.

Enhanced Safety Features

Our spring winding tools securely engage with two winding cone holes during operation, fully supporting spring forces through the handle against the door. This design prevents the accidental release of spring energy, ensuring the wrench cannot detach while under spring torque load.

By eliminating the risks associated with traditional winding bars, such as hand injuries, projectile accidents, ladder falls, and shoulder strain, our tools help reduce workplace injuries and related costs. Avoiding just two days of lost work from a strain or injury can cover the cost of the wrench itself.

Key Safety Benefits

- Worm gear technology prevents the spring from back-driving the tool

- Removes dangers inherent in winding bars

- Minimize fatigue and resulting safety incidents

- Reduces rotator cuff injury

Why Choose our Spring Winding Tools?

Premium Materials

Crafted from highly durable stainless steel and bronze, our spring winding tools are shorter and more compact, delivering greater force compared to competing tools.

Exceptional Winding Performance

Designed to handle more winding in heavy-duty applications without compromising reliability.

Quick Assembly and Disassembly

Intuitive design enables fast assembly, quicker tightening, and easy disassembly, saving valuable time on the job.

High Torque Capability

Delivers high torque levels, making it suitable for even the biggest springs.

Reduced Manual Effort

Innovative design minimizes physical labor, making operation faster and less strenuous.

Plan your visit!

Schedule a visit to our showroom today for a live demonstration of our spring winding tools.

Contact us for a visitDownloads

Surewinder and Brutewinder Flyer

Download this flyer for free for more information about: Spring Winding Tools DownloadHow can we help?

Would you like to know more about how our products and services can help you? Please contact us.