Flatbed: Your Complete Garage Door System in a Box

Knowledge centerThe most convenient product in garage door hardware solutions – our flatbed! A product that not only simplifies your business operations but also saves you valuable time, space, and money. That's exactly what the Flatbed offers: a complete garage door system packaged neatly in a long, flat cardboard box. It's more than just packaging; it's convenience for garage door professionals like you.

Cost Saving

Eliminate reduces costs by eliminating machinery needs and material waste

Cut-to-size

All profiles and seals are cut to size, double checked and ready to install

Minimal Space Required

Slim packaging maximizes storage space, freeing up room for other activities

Consistent Quality

Flatbeds ensure a consistent quality for all garage door hardware

Become a partner

Are you interested in partnering with DOCO and do you want full access to our webshop, configurators and more? Contact us now and plan your visit or online meeting. Plan your meeting nowFeatures

What is a Flatbed?

The concept is simple: a cardboard packaging with all the hardware you need to build your garage door system, cut-to-size and ready to install. The only thing you have to add are your panels and operator.

Flatbeds are also designed to be sustainable by only using cardboard, stackable for maximum truck capacity and an all-in-one solution for garage door professionals like you.

Size

When it comes to flatbeds or door systems in general, you'll often find that there are standard dimensions that cover 80% of your orders. The same goes for our Flatbed packaging which has been optimised for the most common garage door sizes. Our standard* Flatbeds have a length of 3.15 m, a width of 54 cm, and a height of 25 cm. It's important to note that the height includes the cardboard blocks used for forklift operations.

Weight

A Flatbed containing a garage door system with extension springs (HOME-X) has an average weight of around 50 to 60 kg. Our door systems with torsion springs (HOME-F and HOME-R) have an average weight of around 80 kg per flatbed.

How can I order a Flatbed?

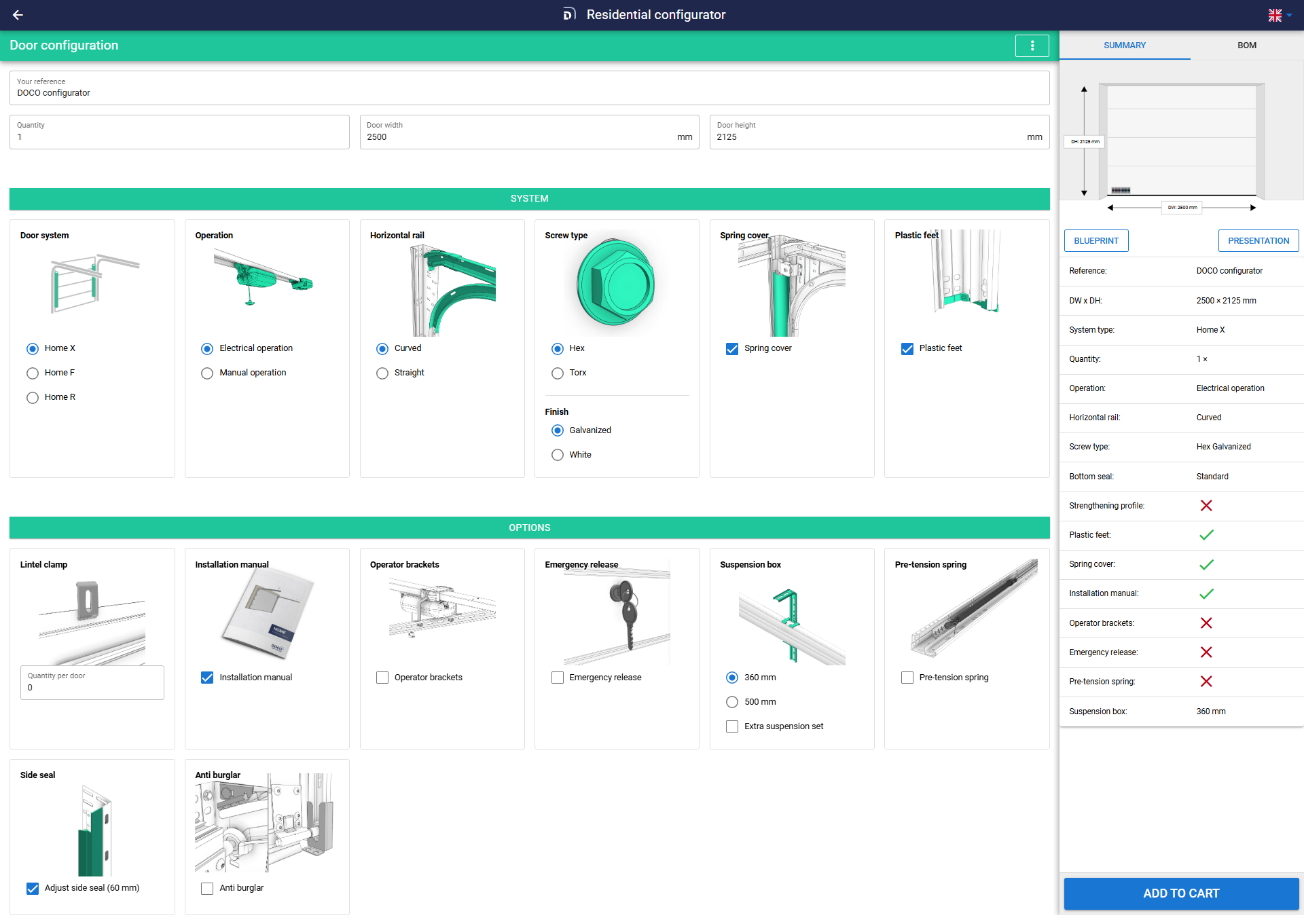

Our intuitive online door configurator is the tool to create and order a garage door tailored to your needs.

With a wide range of customization options, you can easily choose dimensions, optional components, finishes, and other features to suit your specific requirements.

Once you've created your specific garage door, the configurator generates a configuration with a detailed Bill of Materials, making it simple to add your selection to your cart and order it like a standard order. Whether you’re ordering a single flatbed with your custom dimensions and options or configuring multiples of the same design, the process is the same.

Flatbeds allow you to

Stack your panels and operator

Our Flatbed is more than just a container; it's optimised for transport and storage. Its long, flat design allows multiple panels to be stacked on top of the packaging, all while maintaining stability during transport. Speaking of transport, a typical trailer can hold up to 128 flatbeds. No more worrying about damaged or misaligned hardware during shipping. With our Flatbeds, you get your components in perfect condition, every time.

Save space and time

The primary benefit of the flatbed is its exceptional space- saving capabilities. With the flatbed, you no longer need to stock every variant of garage door hardware, because you will receive precisely what you need in a single, compact flatbed. Thus, storage problems can be avoided. This allows you to optimize your storage space and reduce the amount of people working in your in-house production.

Focus on what matters

With the Flatbed, you can shift your focus from production and warehousing to sales. After all that is where your main benefit lies: increasing revenue. . You will save costs since you will no longer need to hire extra manpower and resources to produce hardware. This not only saves you money but also allows you to concentrate on expanding your business and serving customers better.

"The use of DOCO Flatbeds has transformed the way we run our business. The time and space savings alone are the biggest advantages, but there are so many small things that have improved after we started ordering Flatbeds."

- Customer in France

"What we love most about this product it that we know that every box and length is check and sometimes double check. Reliability is the word that comes to mind, because we saw during our tour that there is a level of quality control in every step of the process."

- Customer in Germany

What's in the box?

The content of a standard flatbed*

- Vertical and horizontal track sets, cut to your specific dimensions

- C-profile and lintel profile, cut to your specific dimensions

- Hardware boxes with all hardware for your door system plus all panel specific hardware

- Vertical and horizontal seals

- A suspension set with all components needed for wall/ceiling fixation

- Extension or Tension springs depending on the door system

Optional content

- Spring cover

- Anti burglar hardware

- Pre-tensioned Extension spring

- Operator brackets

- Door handle

- Different types of locks

- Lintel clamps

- Tension bar

Why Choose our Flatbeds?

But how can Flatbeds help me grow my business you ask? Let's go deeper into the many advantages of incorporating Flatbed into your garage door business.

1. All-in-one solution

Time is money, and DOCO recognizes that. With all the essential garage door hardware neatly organized in a single box, your team can work more efficiently. No more searching for individual components or dealing with the hassles of inventory management. The Flatbed ensures you have what you need when you need it, streamlining your operations and allowing you to complete projects faster.

2. Cost saving

One of the most significant advantages of using Flatbed is the substantial cost savings it offers. By eliminating the need for in-house hardware production, you can cut labour costs, reduce the need for expensive machinery and storage space, and minimize material waste. This translates into higher profitability and a healthier bottom line for your business.

3. Space saving

Every square foot of your workspace is valuable. Traditional garage door hardware storage can consume a significant portion of your facility. With Flatbed, you can dramatically reduce your storage requirements. The slim profile of the packaging means you can store more in less space, freeing up room for other essential activities, whether it's expanding your inventory or creating a more comfortable working environment.

4. The best hardware available

Flatbeds are not just about convenience; it's about ensuring the quality of your garage door installations. Every component included in the Flatbed is designed and tested by our R&D department to meet all the industry standards. This means you can have confidence in the reliability and performance of the hardware you're using, which helps you build an even better business reputation.

5. High quality process

We take pride in producing our Flatbeds at our state-of-the-art production facility, where we've dedicated not just one but two production lines solely to the production of your custom-made garage door systems. Some highlights of our production lines: Automated sawing, digital control measurements, visual end control, a pre-tensioned workbench and more. All of this ensures that we can meet your demands promptly and respond quickly, maintaining a consistent supply of Flatbeds for your business.

Plan your visit or try the configurator for yourself

Plan your visit today and get a tour of our production facility where you can see all the steps in the process and ask all the questions you may have. Our sales managers are happy to guide you through the entire production process, from A to Z, so you can witness first-hand how a standard* Flatbed can help your business grow. Don't miss this opportunity to see innovation in action.

Plan your visit Start configuring now* There is no such thing as a standard Flatbed, because we try to meet every customers' expectation and wishes

How can we help?

Would you like to know more about how our products and services can help you? Please contact us.